PUR laminate/adhesive for silicone

PUR as adhesive/laminate for silicone bonding Solutions for various Industries through Compo-SiL®

With the growing sustainability trend, the demand of sustainable materials over their plastic counterparts have also been increased drastically. People are looking for sustainable solutions for a better lifestyle.

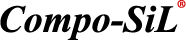

Silicone

Silicones are one of the sustainable, bio-compatible and manmade polymers which is derived from silica or sand. Silicones have many uses in a variety of industries and consumer products because of its high value added elastomeric and other key properties:

PUR Adhesive

In adhesive industry, PUR represents as one of the environmental friendly solvent-free laminating structural adhesive technology to bond well with diverse substrates like metals, glass, ceramics, wood and some plastics, in general is an excellent adhesive for hard to bind materials with reduce processing time.

Adhesive solutions like PUR along with Silicone materials can be a sustainable solution in various industries specifically in Textile, Electronic, Car Assembly, Woodworking Lamination industries, Biomedical Material Adhesive etc. with unlimited design of freedom.

How to bind silicone with PUR adhesive for different applications?

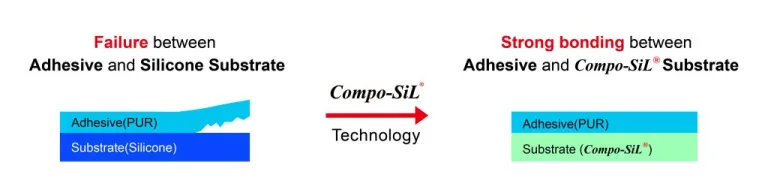

Silicone being one of the low surface energy materials always results weaker adhesion strength with other adhesive. With 50 years of expertise in silicone, GS has been able to solve this problem through it’s Compo-SiL® technology.

Compo-SiL® has opened the door to bond Silicone Rubber with Existing PUR adhesive technology that will solve the adhesive failure between silicone and PUR adhesive with other substrates.

Compo-SiL®: An easy solution for Silicone bonding with PUR adhesives.

This silicone based composite Compo-SiL® can be the perfect choice for the industries following the sustainable trend. By choosing Compo-SiL®, industries can have diverse applications where there was an extreme difficulty of bonding cured silicone with other functional materials.

Now with Compo-SiL® technology, the high adhesion properties of polyurethane could be combined with silicone for diverse applications and unmet possibilities.

Why PUR Industry wants silicone bonding solution?

- PUR and Compo-SiL® together can provide solution to the customers who demanded silicone surface with various materials like textile, wood, glass or metals. This solution has advantages like easy bonding process, solvent free and room temperature process.

- Customers’ demands more sustainable products for which silicone is the best choice.

- Silicone products can be highly durable as silicone itself is long lasting and endures extreme temperature fluctuations without melting, cracking or otherwise degrading. Also, it resists oxidative deterioration (normal aging) for decades on end which consequently increases the product lifecycle.

- As the world is moving towards sustainability as its priority, the adhesive industry itself wants to show themselves as a sustainable solution provider using silicone.

How PUR Industry will get a silicone bonding solution? Compo-SiL® Technology

- It can bridge the gap between adhesive industry and silicone bonding.

- General Silicones high quality silicone-based Compo-SiL® films have a modified layer above silicone which provides a solution for the PUR industry to bond silicone films.

- It is a totally dry process that doesn’t require any primers can be easily integrated in the process flow of PUR Adhesive Industry.

PUR can be used as an adhesive or a laminate material for silicone bonding solutions through Compo-SiL®

- Fabric Lamination with Silicone surface: The textile industry has much demand for sustainable ways to bind silicone with their fabric. Although there are processes like liquid silicone coating on textile but comes with the limitation of only big size, time taking and cost. Compo-SiL® based silicone with PUR can be bonded so easily on textile that too on room temperature as the PUR has room temperature process and silicone is also cured one!

- Laminate for Polymer films: Various Thermoplastic as well as thermoset polymer films like TPU, PC, ABS and many more can be easily bonded to silicone now through Compo-SiL® by using PUR as a laminate or adhesive in some cases.

- Leather Industry: As the conventional leather manufacturing processes requires a specific fabric to be bonded on one side. Also, in sustainability trend people are moving towards alternative solutions to animal leather, silicone being the 1st choice. Combining Compo-SiL® technology with PUR to have sustainable solution for leather industry is also a great possibility.

- Encapsulation in Electronics Industry: Silicone has already proven itself to be a great encapsulation material for various applications, one of which is for the electronics industry. As the soft and wearable electronics is growing PUR with Compo-SiL® silicone rubber not only binds to the substrates/textile with electronics on it, but also provides the encapsulation at the same time.

PUR as laminate/adhesive with Compo-SiL® silicone rubber can be implement in many areas that have not mentioned above such as for gasket industries as silicone has proven itself to be a very good gasket material. Also, those gaskets need to be bonded with various surfaces where this concept can be helpful. The applications can be tunable as per the end user requirements. Compo-SiL® silicone can be applicable to all the applications where PUR is used as a laminate or adhesive.